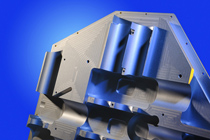

Pre-treatment

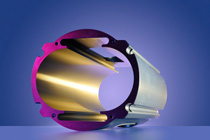

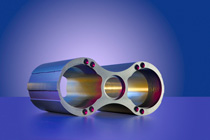

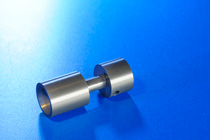

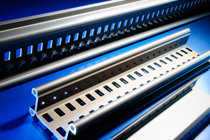

Masking

All unprotected parts not made of aluminium, titanium or magnesium will be severely corroded during an anodising surface treatment, which usually leads to an unusable product.

Screw threaded inserts (e.g. Heli-Coil), other inserts, and other non-aluminium parts should preferably be fitted after the surface treatment. Since this is not always possible, Surface Treatment will mask off any such parts. In addition, various masking techniques are used to make it possible to combine various surface treatments in one product.

There are various masking methods available. Each masking technique has its own advantages and disadvantages. In order to overcome a variety of problems we often use various masking techniques on one product. Critical areas must always be identified in advance. When certain parts may not be treated, for whatever reason, a run-out zone must be designated.

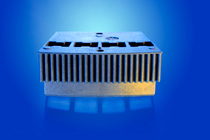

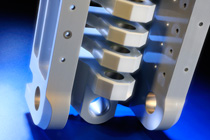

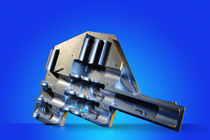

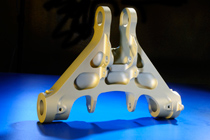

Tumbling

For a product to be suitable for tumbling, a number of conditions must be met. The most important thing is that they will not be damaged by the tumbling operation, and that they will not become entangled. The drum contains small stones or some other material with a certain shape and hardness, which is suitable for the parts being treated and will produce the result one intends.

For rough deburring, heavier and rougher stones and abrasives can be used. For finer treatment, one must use fine abrasives and smooth media. For drum polishing, smooth steel balls are usually used, but this is not suitable as a pre-treatment for anodising. The smaller the balls are, the more attractive the result will be. Glass beads are also used for this purpose. It is wise to conduct a number of tests to determine how best to proceed.

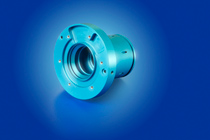

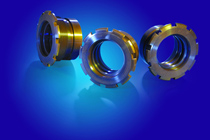

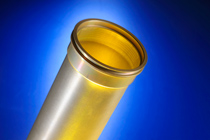

Pickling

Pickling removes impurities from the surface of a metal. Surface Treatment uses the pickling technique to remove contaminants and attain a clean, uniform starting condition for the following process steps. Surface Treatment performs the following pickling processes in-house:

- Alkaline pickling

- Chemical etching

- Chromic acid pickling

- Bright pickling

In addition, Surface Treatment has special baths that are used for the de-anodising process.

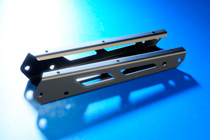

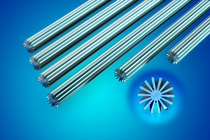

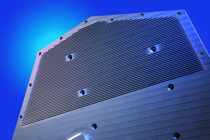

Blasting

Aluminium can also be blasted. A slightly roughened surface is obtained through glass bead blasting, which also removes small burrs and sharp edges. Glass bead blasting followed by an anodising treatment results in a velvety surface.

"Anodiseur"